Metso HP cone crusher parts

Metso HP cone crusher parts

Comprehensive Range of Cone Crusher Parts for Nordberg HP Series

Our company specializes in providing high-quality assembly parts and spare wear parts for a wide range of Nordberg HP Series cone crushers, including HP3, HP4, HP5, HP6, HP200, HP300, HP400, HP500, HP700, and HP800 models.

Key Components

Main Frame: The robust foundation of your crusher, designed to withstand the toughest conditions. It provides structural integrity and supports all other components.

Adjustment Ring: This component allows for precise control over the crusher's closed-side setting (CSS), ensuring optimal crushing performance and product gradation.

Countershaft: A critical component that drives the crusher's crushing action. It transmits power from the motor to the eccentric assembly, enabling the gyratory motion necessary for crushing.

Eccentric: The eccentric assembly is responsible for the gyratory motion of the crusher head, which is essential for effective crushing. It works in conjunction with the main shaft and bushings.

Socket: The socket provides a secure fit for the crusher's main shaft, ensuring smooth operation and reducing wear on other components.

Socket liner: The socket line provides a smooth operation of the socket assembly, reducing friction and wear on the main shaft.

Head: The head is the upper section of the crusher that houses the mantle and other key components. It plays a crucial role in the crushing process by applying force to the material.

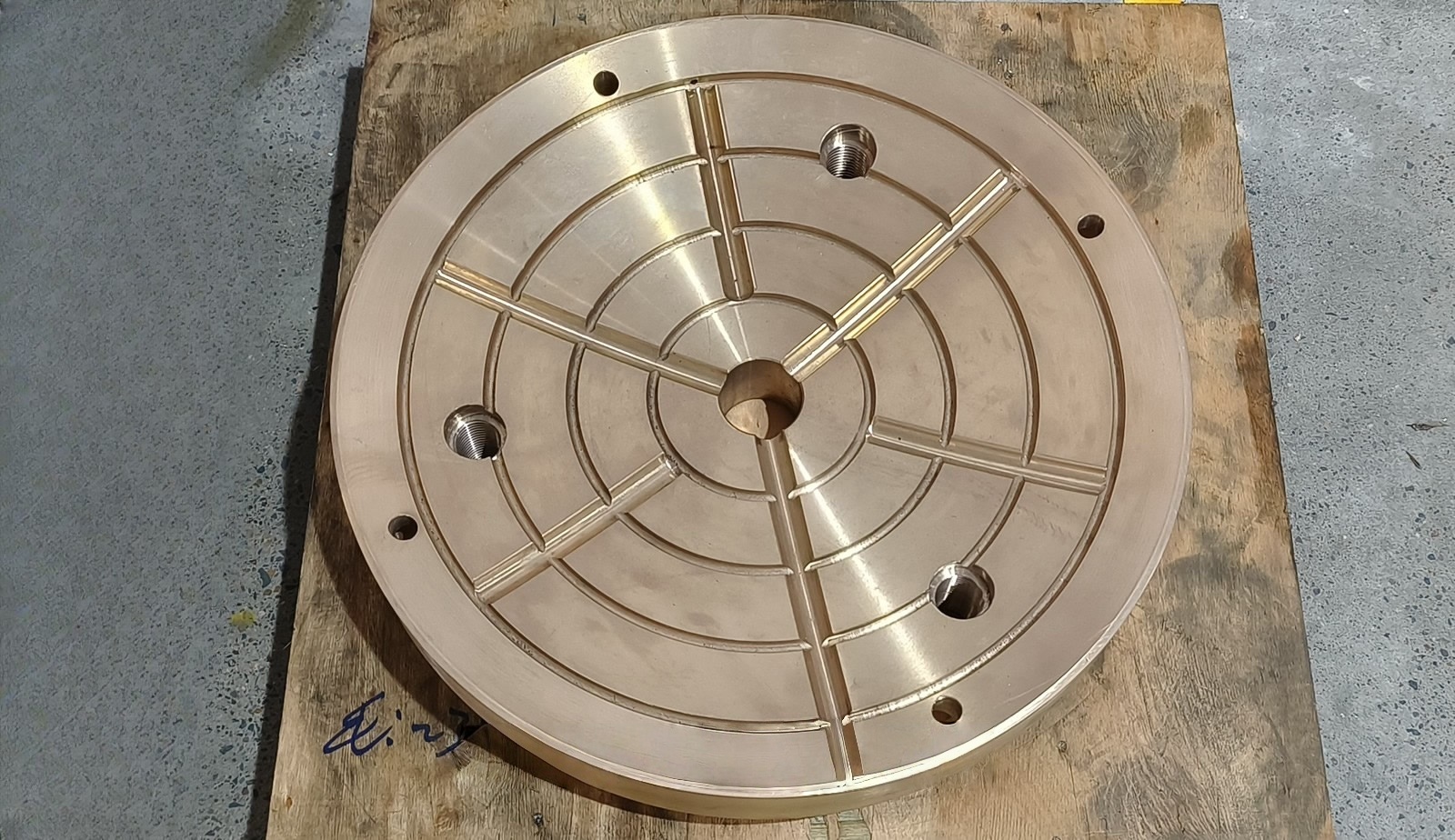

Feed Plate: This component directs material into the crushing chamber, ensuring even distribution and efficient processing. It helps prevent uneven wear and extends the life of the crusher.

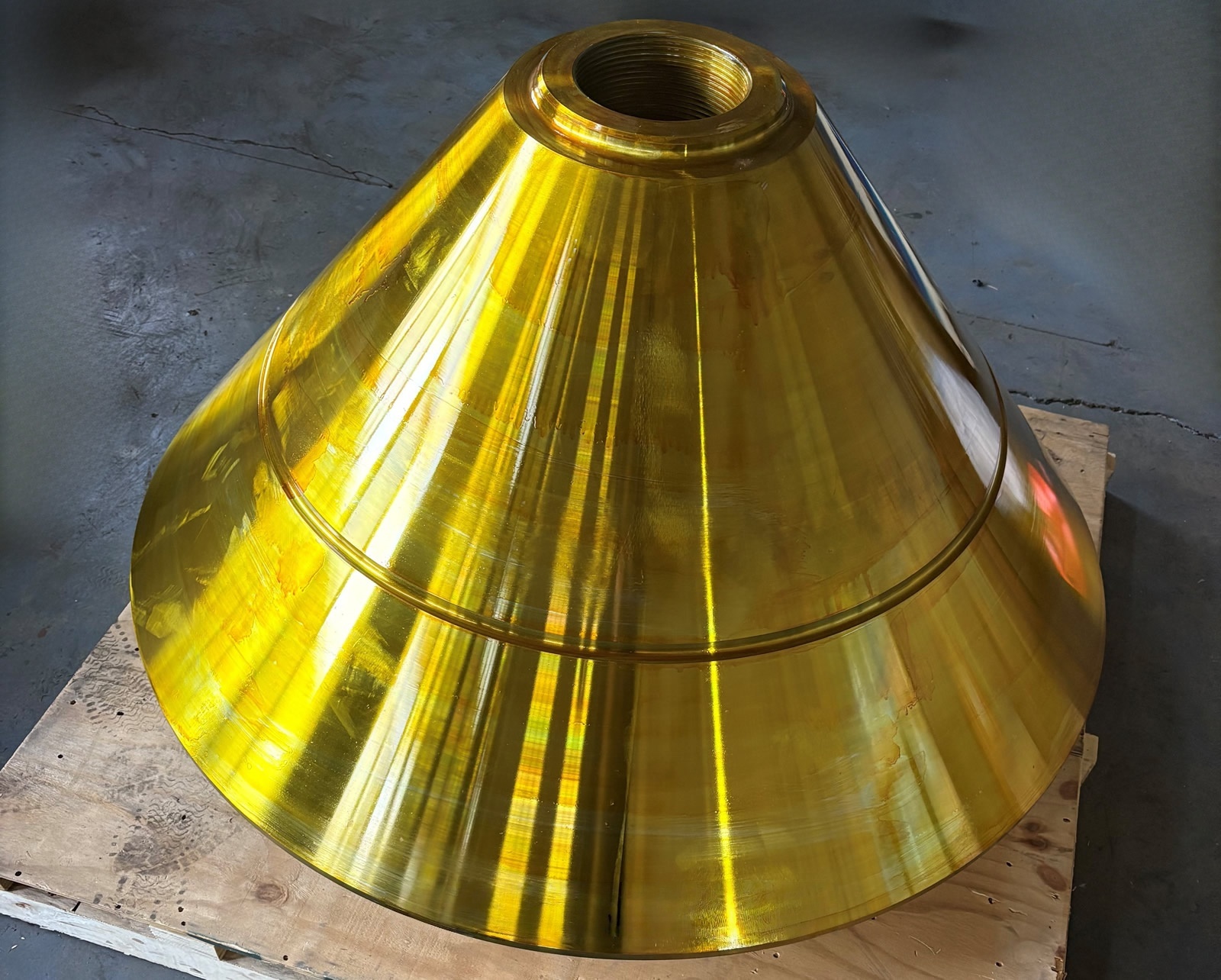

Bowl: The bowl is the lower section of the crusher that works in conjunction with the mantle to crush material. It is lined with replaceable bowl liners to protect against wear.

Main Frame Liner: These liners protect the main frame from wear caused by the constant impact of material. They are replaceable and help extend the life of the crusher.

Arm Guard: The arm guard shields the crusher's arms from damage during operation, reducing the risk of costly repairs and downtime.

Main Shaft: The main shaft is the central component that supports the crusher's moving parts. It is critical for maintaining the alignment and stability of the crusher.

Piston: Part of the hydraulic system, the piston is used to adjust the crusher's settings and clear the crushing chamber in case of a blockage.

Eccentric Bushing: This bushing ensures smooth operation of the eccentric assembly, reducing friction and wear on the main shaft.

Drive Gear: The drive gear transmits power from the motor to the crusher's moving parts, enabling the crushing action.

Pinion: The pinion works with the drive gear to facilitate the crusher's operation. It is a critical component in the power transmission system.

Counterweight: The counterweight balances the crusher's moving parts, reducing vibration and wear during operation.

Head Bushing: This bushing provides a smooth surface for the head to rotate on, reducing friction and extending the life of the head assembly.

Bowl Liner: The bowl liner is the replaceable surface that comes into direct contact with the material being crushed. It is designed to withstand high wear and can be replaced as needed.

Mantle: The mantle is the primary wear surface that crushes the material against the bowl liner. It is available in various profiles to suit different crushing applications.