Metso MP cone crusher parts

Metso MP cone crusher parts

Comprehensive Parts Supply for Metso MP Series Cone Crushers

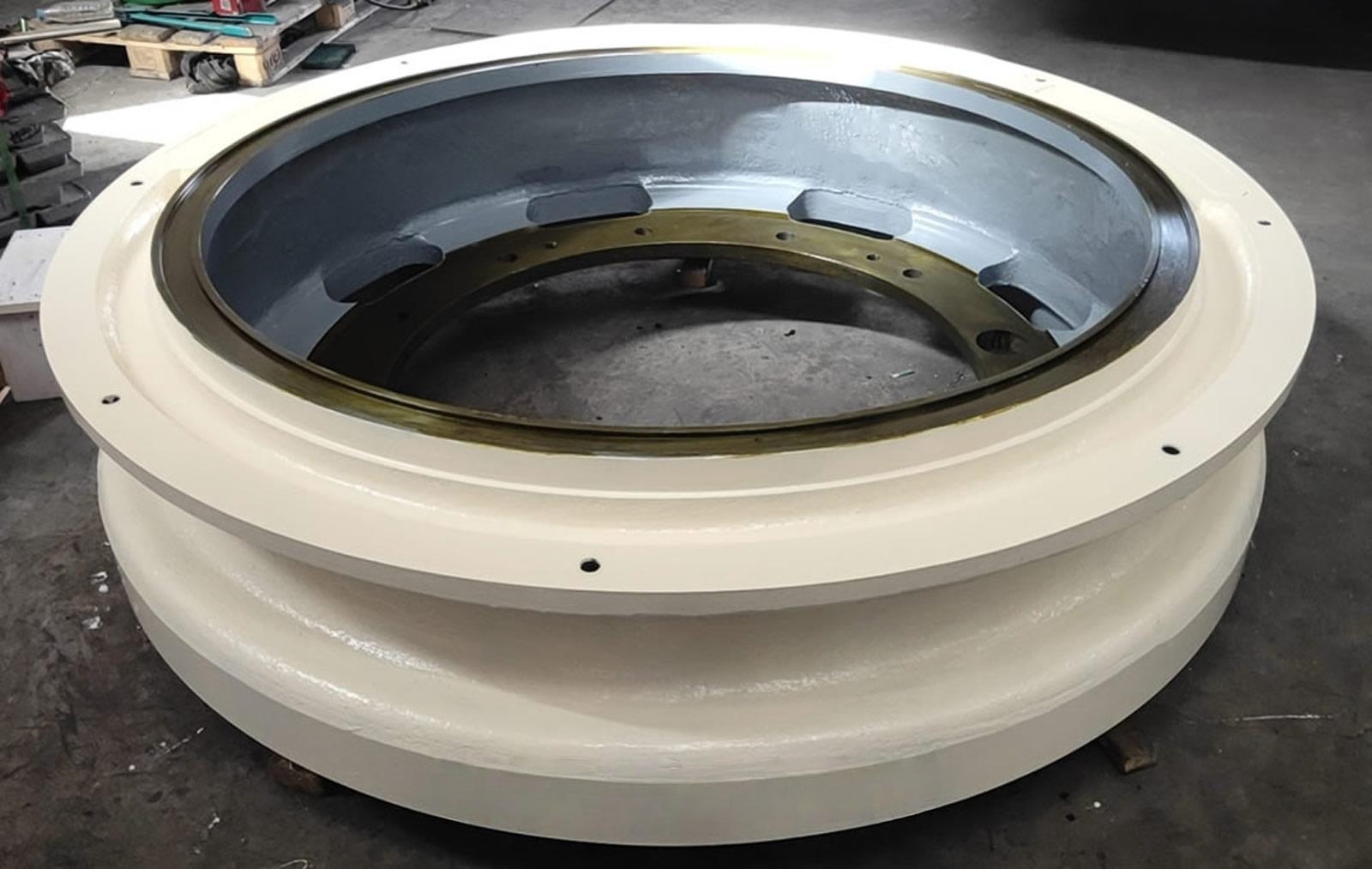

Main Frame: The robust main frame is designed to withstand maximum crushing loads, ensuring durability and stability during operation.

Adjustment Ring: This component allows for precise control of the crusher setting, enabling consistent size reduction and efficient operation.

Eccentric: The eccentric assembly is engineered to provide maximum throughput and crushing efficiency, crucial for both coarse and fine crushing applications.

Socket: The socket liner offers maximum head support and multiple oil grooves for full lubrication, ensuring smooth operation and reduced wear.

Head: The head assembly is designed to sustain high crushing loads, with features that reduce head spin and ensure reliable performance.

Feed Plate: Replaceable feed plates distribute incoming feed evenly, protecting the crusher from uneven wear and enhancing overall efficiency.

Bowl: The rotating bowl compensates for feed segregation and ensures even wear in the crushing cavity, maintaining consistent crusher settings.

Main Shaft: Forged from high-strength alloy steel, the main shaft distributes oil to various high-performance bearings, ensuring smooth and reliable operation.

Eccentric Bushing: This component supports the eccentric assembly, providing strength and durability for dependable power transmission.

Upper Thrust Bearing: Designed to handle high crushing forces, the upper thrust bearing ensures smooth operation and reduces wear on other components.

Counterweight: The counterweight reduces unbalanced forces created by the rotating eccentric, enhancing the crusher's efficiency and stability.

Socket Liner: This liner provides maximum head support and ensures full lubrication of the gyrating head ball, crucial for maintaining performance.

Head Bushing: The head bushing is uniquely designed to reduce head spin and ensure smooth operation, even under high crushing loads.

Frame Seat Liner: This liner provides extra protection to areas exposed to material passing through the crusher, enhancing durability and performance.

Upper Head Bushing: Designed to reduce head spin, this bushing ensures reliable performance and reduces wear on other components.

Bowl Liner: The bowl liner is designed for even wear and maximum metal utilization, ensuring consistent size reduction and efficient operation.

Mantle: The mantle is crucial for achieving the desired crushing performance, with designs that ensure optimal particle shape and size reduction.

HYD Drive Assy: Responsible for providing precise hydraulic control to optimize crusher performance and protect critical components during operation. It integrates hydraulic power and automation to manage adjustments, overload protection, and operational stability.