Sandvik CS cone crusher parts

Sandvik CS crusher parts

Detailed Introduction to Our Sandvik CS Series Cone Crusher Parts

Below is a detailed overview of the parts we offer and their significance in the operation of Sandvik cone crushers.

Key Parts We Supply

Spider Bushing: This critical component supports the spider assembly and ensures smooth operation of the crusher. It is designed to withstand high loads and reduce wear on the spider.

Seal Ring: The seal ring prevents dust and other contaminants from entering the crusher's internal mechanisms, thereby protecting the crusher's longevity and reducing maintenance needs.

Support Ring: This ring provides structural support to the crusher's upper section, ensuring stability during operation.

Arm Shield: The arm shield protects the crusher's arms from wear and tear, extending the life of the crusher's moving parts.

Concave Ring: This ring is crucial for the crushing process, as it forms the crushing surface along with the mantle. It is designed to handle high-impact forces and abrasive materials.

Filler Ring: The filler ring helps maintain the proper alignment and spacing within the crusher, ensuring efficient crushing performance.

Hose: High-quality hoses are essential for the hydraulic system, ensuring smooth and reliable operation of the crusher's adjustment mechanisms.

Mantle: The mantle is one of the most critical wear parts in a cone crusher. It works in conjunction with the concave to crush the material. Our mantles are made from high-quality materials to ensure long-lasting performance.

Wear Plate: Wear plates protect the crusher's body from abrasion and impact, reducing the need for frequent replacements and maintenance.

Topshell: The topshell houses the upper section of the crusher, including the mantle and concave. It is designed for easy access and maintenance.

Boss: The boss is a key component that connects the mainshaft to the crusher's structure, ensuring proper alignment and smooth operation.

Bottom Shell Bushing: This bushing supports the bottom shell and reduces friction, ensuring smooth rotation of the crusher's components.

Foot: The foot provides a stable base for the crusher, ensuring it remains securely in place during operation.

Liner Narrow Arm: This component protects the crusher's arms from wear, extending the life of the crusher's moving parts.

Eccentric Wearing Plate: The eccentric wearing plate is designed to withstand the high forces generated during the crushing process, ensuring long-lasting performance.

Bracket: Brackets provide structural support to various components of the crusher, ensuring stability and reliability.

Liner Pinionshaft Arm: This component protects the pinionshaft arm from wear, ensuring smooth operation of the crusher.

Bottomshell: The bottomshell houses the lower section of the crusher, including the eccentric and mainshaft. It is designed for easy access and maintenance.

Pinion Shaft Housing: This housing protects the pinion shaft and ensures proper alignment, reducing wear and tear on the crusher's components.

Bearing Cover: The bearing cover protects the crusher's bearings from dust and contaminants, ensuring smooth operation and reducing maintenance needs.

Spacer: Spacers are used to maintain proper spacing between components, ensuring efficient operation of the crusher.

Pinion Shaft: The pinion shaft is a critical component that drives the crusher's eccentric, ensuring smooth and reliable operation.

Hub: The hub connects the pinion shaft to the crusher's structure, ensuring proper alignment and smooth operation.

Eccentric: The eccentric is a key component that drives the crusher's crushing action. It is designed to withstand high forces and ensure long-lasting performance.

Ring: Rings are used to maintain proper alignment and spacing within the crusher, ensuring efficient crushing performance.

Key: Keys are used to secure various components of the crusher, ensuring they remain in place during operation.

Eccentric Bushing: The eccentric bushing reduces friction and wear on the crusher's eccentric, ensuring smooth operation.

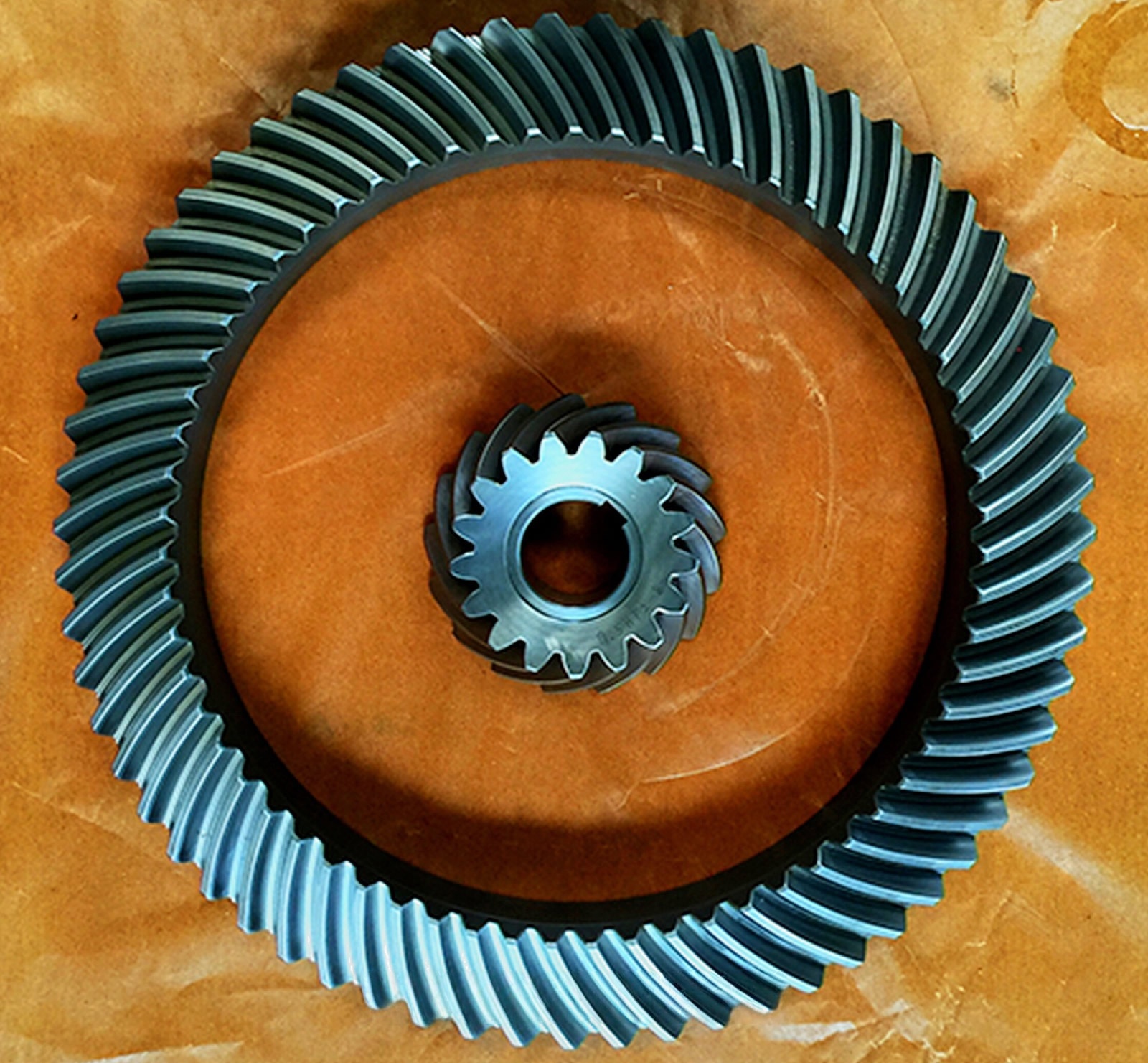

Gear and Pinion: The gear and pinion are critical components that drive the crusher's eccentric, ensuring smooth and reliable operation.

Inner Head Nut: The inner head nut secures the mainshaft in place, ensuring proper alignment and smooth operation.

Mainshaft Sleeve: The mainshaft sleeve protects the mainshaft from wear and tear, ensuring long-lasting performance.

Retaining Ring: Retaining rings are used to secure various components of the crusher, ensuring they remain in place during operation.

Dust Seal Ring: The dust seal ring prevents dust and contaminants from entering the crusher's internal mechanisms, reducing maintenance needs.

Retainer: Retainers are used to secure various components of the crusher, ensuring they remain in place during operation.

Scraper: The scraper removes debris from the crusher's components, ensuring smooth operation and reducing maintenance needs.

Burning Ring: The burning ring is designed to withstand high temperatures, ensuring long-lasting performance in high-heat environments.

Mainshaft: The mainshaft is a critical component that drives the crusher's crushing action. It is designed to withstand high forces and ensure long-lasting performance.

Head Center: The head center supports the mainshaft and ensures proper alignment, reducing wear and tear on the crusher's components.

Seal Ring Inner: The inner seal ring prevents dust and contaminants from entering the crusher's internal mechanisms, reducing maintenance needs.

Locating Bar: The locating bar ensures proper alignment of the crusher's components, ensuring efficient operation.

Gasket: Gaskets are used to create a seal between various components of the crusher, preventing leaks and ensuring smooth operation.

Shim: Shims are used to adjust the spacing between components, ensuring proper alignment and efficient operation.

Dust Collar Inner: The inner dust collar prevents dust and contaminants from entering the crusher's internal mechanisms, reducing maintenance needs.

Hydroset Cylinder: The Hydroset cylinder is a key component of the crusher's hydraulic adjustment system, ensuring smooth and reliable operation.

Hydroset Cylinder Bushing: The Hydroset cylinder bushing reduces friction and wear on the Hydroset cylinder, ensuring long-lasting performance.

Packing Clamp Plate: The packing clamp plate secures the packing in place, ensuring a proper seal and preventing leaks.

Piston Wearing Plate: The piston wearing plate is designed to withstand high forces, ensuring long-lasting performance in the crusher's hydraulic system.

Step Washer: Step washers are used to maintain proper spacing between components, ensuring efficient operation of the crusher.

Mainshaft Step: The mainshaft step ensures proper alignment of the mainshaft, reducing wear and tear on the crusher's components.

Piston: The piston is a key component of the crusher's hydraulic system, ensuring smooth and reliable operation.

Chevron Packing: Chevron packing is used to create a seal in the crusher's hydraulic system, preventing leaks and ensuring smooth operation.

Plug: Plugs are used to seal various openings in the crusher, preventing leaks and ensuring smooth operation.

Hydroset Cylinder Cover: The Hydroset cylinder cover protects the Hydroset cylinder from dust and contaminants, ensuring smooth operation and reducing maintenance needs.