Vertical impact crusher parts

Metso Barmac and Sandvik VSI Impact Crusher Parts

We offer a wide range of spare parts for Metso Barmac and Sandvik VSI impact crushers, including models such as B6150, B7150, B9100, and Sandvik CV series (e.g., CV229, CV228, CV218, CV217, CV216, CV215, etc.).

Key Parts Include:

SHAFT ASSEMBLY

The shaft assembly is one of the core components of a VSI crusher, responsible for transmitting power and supporting the rotor. Our shaft assemblies are precision-engineered for high strength and long service life.

RELAY

Relays are critical components in the electrical control system, ensuring automation and safe operation. We provide high-quality relays to ensure the stability and reliability of your equipment.

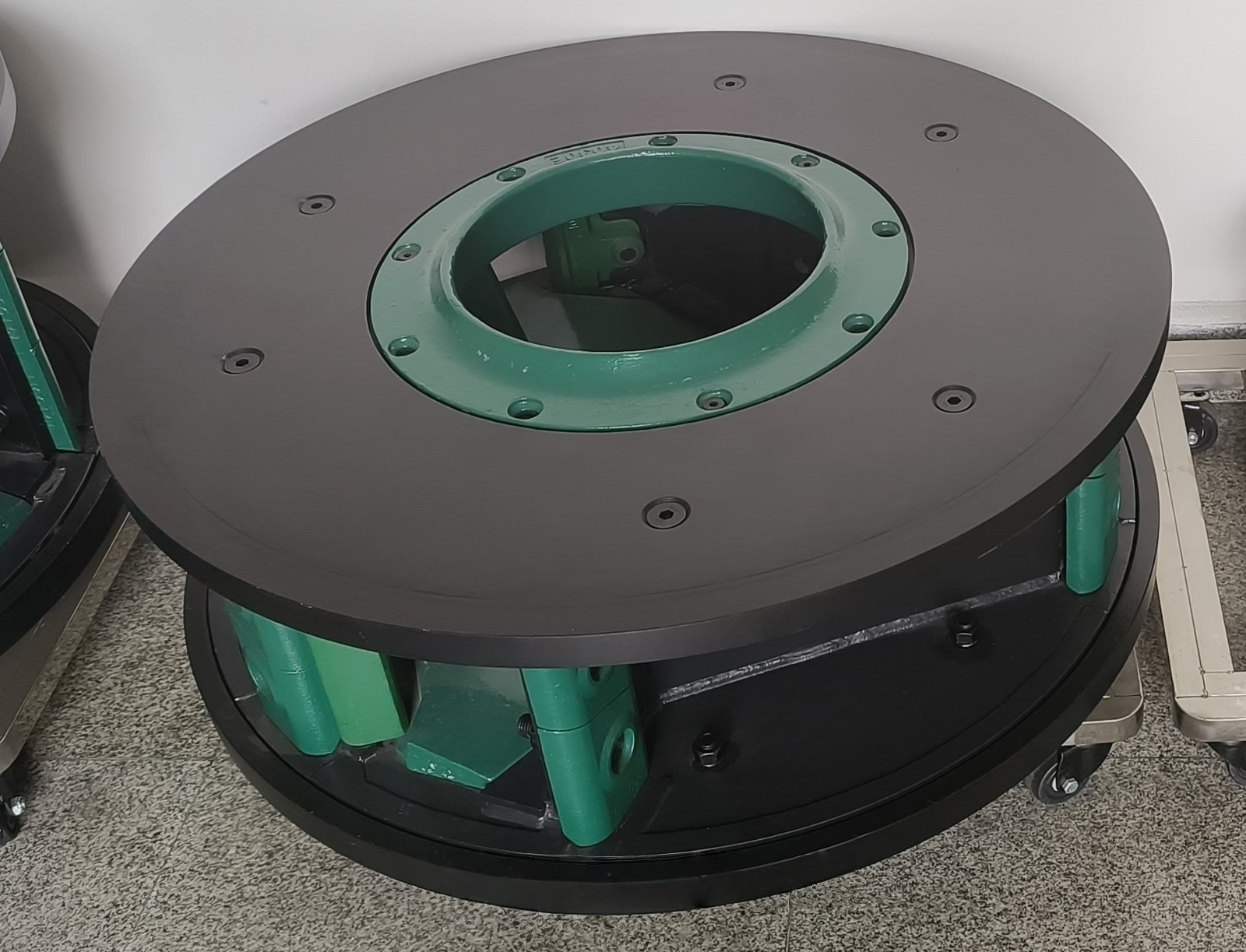

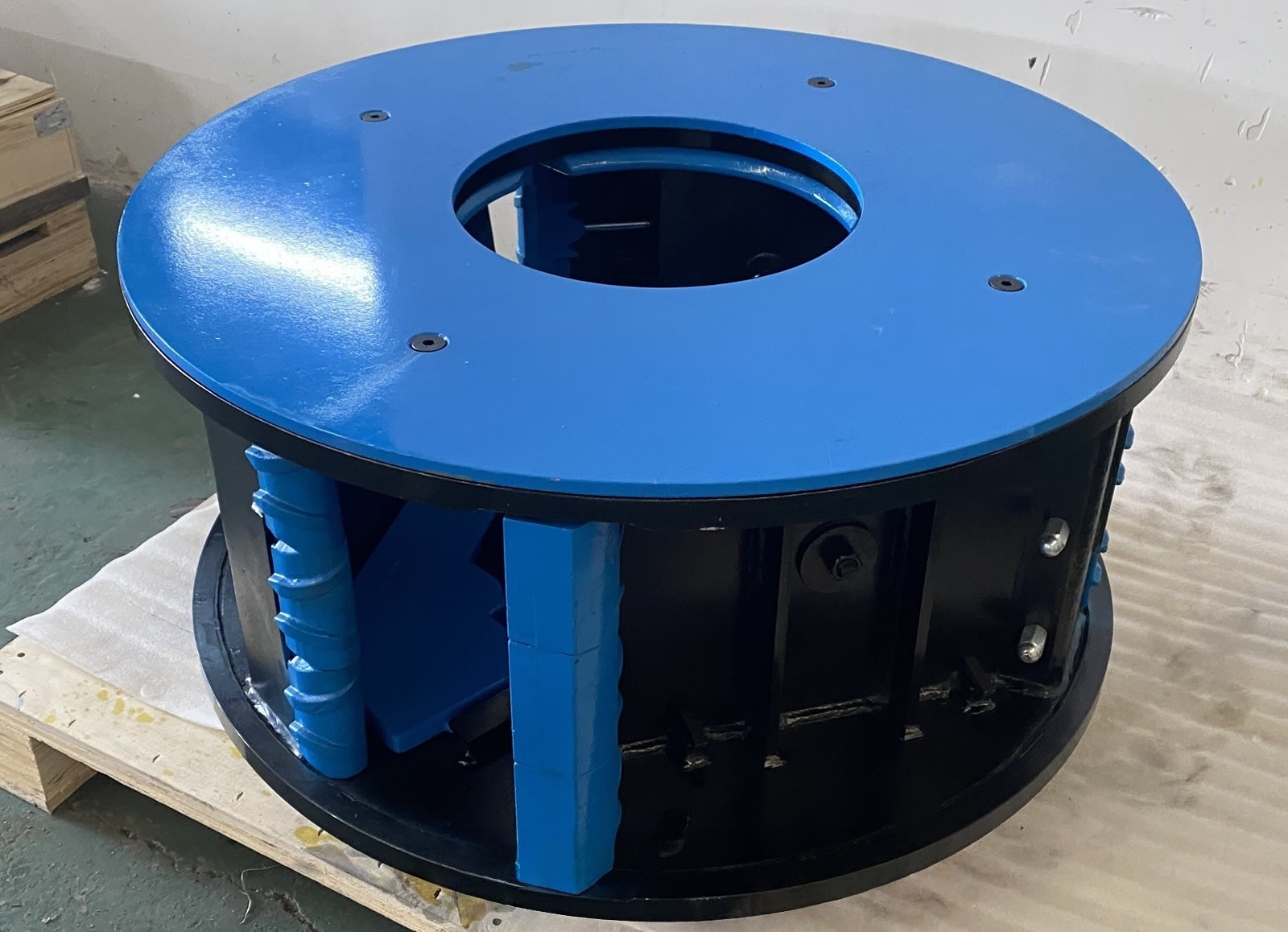

Basic Rotor Assembly

The rotor assembly is a key component of the VSI crusher, directly impacting crushing efficiency and product quality. Our rotor assemblies are optimized for stable performance under high loads, reducing wear and maintenance costs.

WEAR RUBBER

Wear rubber is used to protect the internal structure of the crusher, reducing the impact and wear caused by materials. Our wear rubber offers excellent abrasion resistance and impact resistance, extending the lifespan of your equipment.

SPIDER FRAME

The spider frame supports the rotor and distributes material evenly. Our spider frames are made from high-strength materials, ensuring stable operation even under high-pressure conditions.

FEED PLATE

The feed plate guides material into the crushing chamber, ensuring even distribution. Our feed plates are specially treated for superior wear and impact resistance.

Wear Plate

Wear plates protect the internal structure of the crusher, reducing material-induced wear. Our wear plates are made from high-strength materials, ensuring reliable performance in harsh conditions.

BACKUP TIP SET

Backup tip sets are used to replace worn tips, ensuring consistent crushing efficiency. Our tip sets are precision-machined for a perfect fit with your equipment.

TOP PLATE

The top plate protects the upper structure of the crusher, reducing material impact and wear. Our top plates are made from high-strength materials, ensuring stability under high-pressure conditions.

Rotor Tip Set

Rotor tip sets are critical for material crushing, directly affecting efficiency and product quality. Our rotor tip sets are designed for stable performance under high loads, reducing wear and maintenance costs.

HANGER TIP SET

Hanger tip sets support and secure rotor tips, ensuring stability during high-speed rotation. Our hanger tip sets are made from high-strength materials, ensuring reliable performance in demanding conditions.

HUB

The hub connects the rotor to the shaft, ensuring stable power transmission. Our hubs are precision-machined for high strength and long service life.

Bottom Tip Wear Plate Set

Bottom tip wear plate sets protect the lower structure of the crusher, reducing material impact and wear. Our wear plate sets are made from high-strength materials, ensuring reliable performance in harsh conditions.

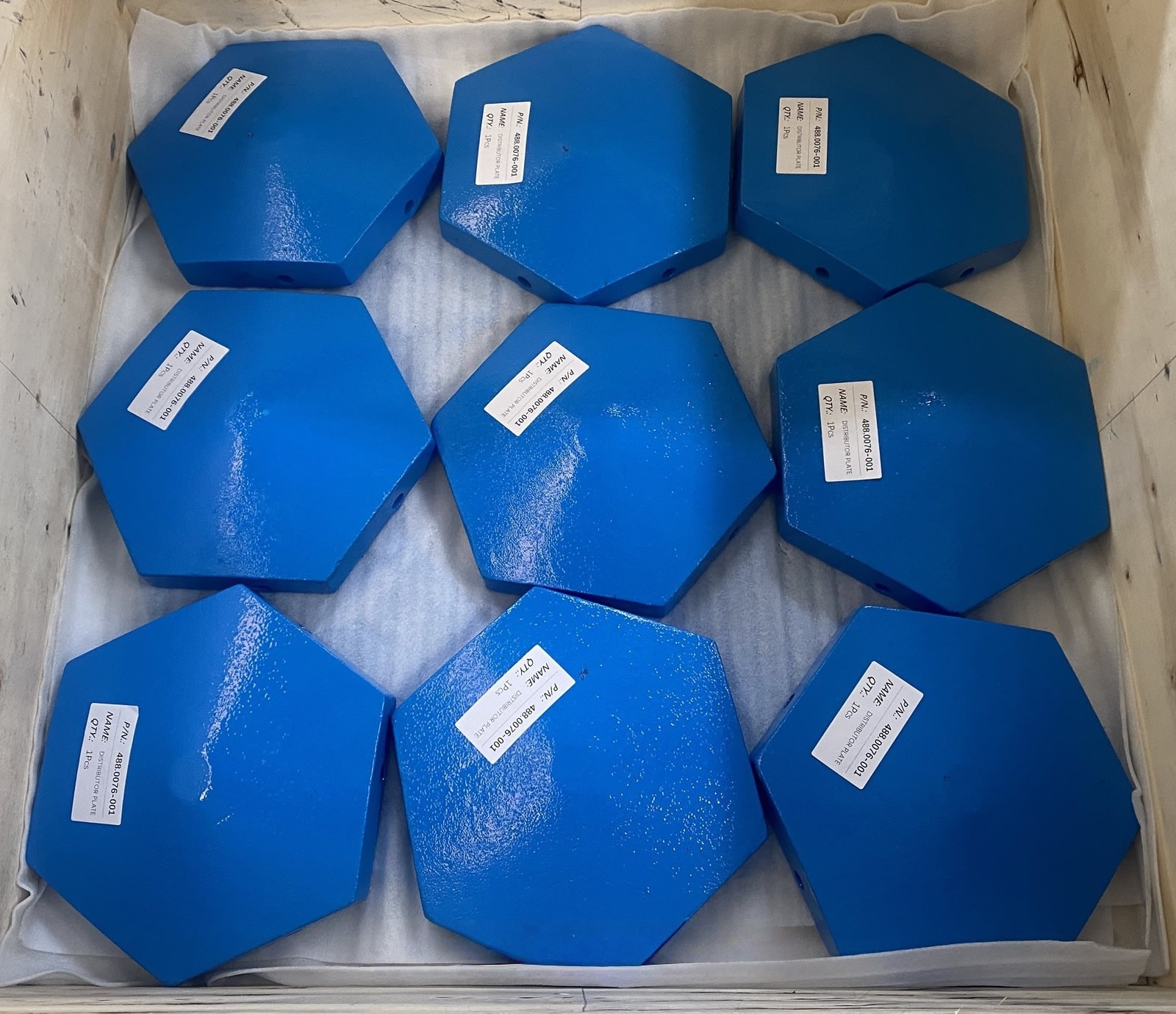

Distributer

The distributer ensures even material distribution into the crushing chamber, maximizing crushing efficiency. Our distributers are optimized for uniform material flow, reducing equipment wear.

Bare Rotor

The bare rotor is a core component of the VSI crusher, directly impacting crushing efficiency and product quality. Our bare rotors are precision-machined for stable performance under high loads, reducing wear and maintenance costs.